Sleipner E Series: Get rolling in minutes

What is the best way to transport an excavator? To enjoy the full wheeled advantage of dollies, a quick and easy set up and unmounting are vital. Sleipner E Series dollies are designed to get you rolling in no time. In fact, it takes less than two minutes to drive the tracks of your excavator onto a Sleipner E Series dolly. After that, you simply turn the upper carriage around and place the bucket on the bed of the truck. Then, by lifting the tracks up by pushing the bucket down, you are good to go. Simple, safe and effective!

The wheeled advantage

REDUCE TRAVEL TIME BY UP TO 85%

Replace three hours of tramming with a half an hour of smooth riding

INCREASE EXCAVATOR PRODUCTIVITY BY 12–20%

Convert tramming hours into excavating hours

SAVE ON UNDERCARRIAGE MAINTENANCE BY 50%

Bumpy tramming is stressful for the undercarriage of excavators

REDUCE LIFE CYCLE COSTS BY 10–18%

Less maintenance with fewer spare parts, lower fuel consumption

Why choose the Sleipner E Series?

Tracks are good for excavating, but not so good for moving. A typical excavator spends 7 to 30% of its working days tramming – time that can be reduced up to 85% by using Sleipner E Series dollies. Designed for safe and fast set up and unloading, Sleipner E Series dollies are a cost-effective, time-saving alternative to lowbed trailers. Get on wheels, hitch a ride on a truck and get there faster, more smoothly and more safely – and also with less undercarriage damage and fewer greenhouse emissions.

READY TO GO

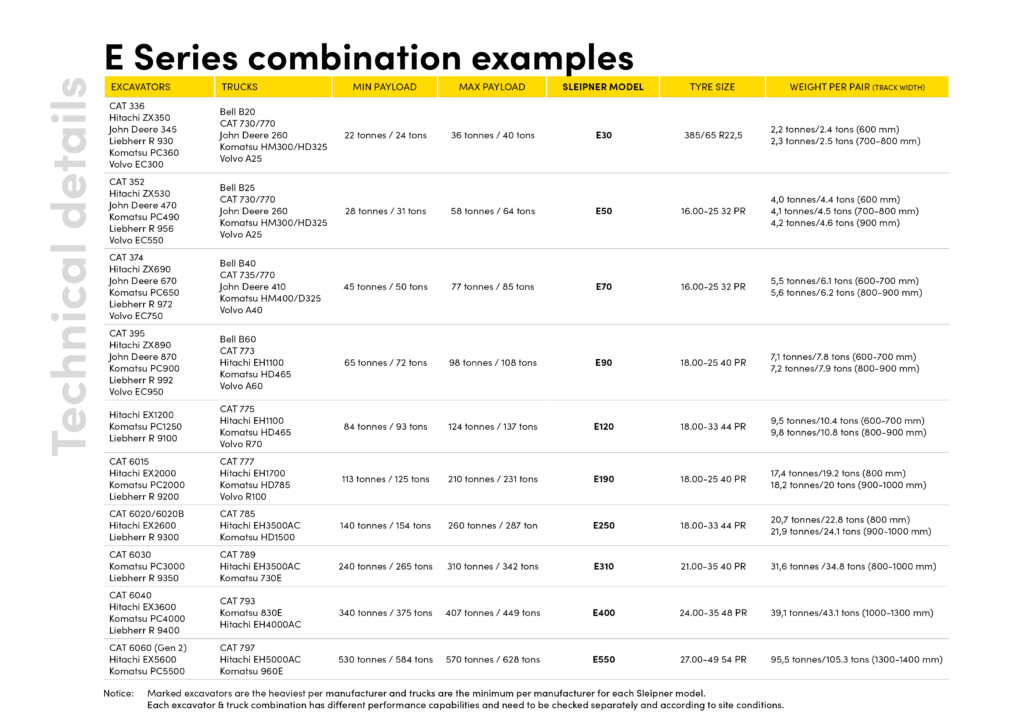

Sleipner E Series dollies are designed for excavators weighing 23 to 570 metric tonnes. With their quick and easy implementation, you can start to enjoy the wheeled advantage within days! There are several models available to match the weight and dimensions of your machinery.

MORE WORKING HOURS

Instead of three hours traveling on tracks, your excavator can be transported in half an hour on Sleipner E Series dollies. The two and half hours you save can then be used for productive work, allowing the loading to be planned more efficiently. The improved utilisation and availability rates can increase your excavator’s productivity by 12 to 20%.

LONGER UNDERCARRIAGE LIFE

Undercarriage parts and maintenance can account for up to one-third of an excavator’s life cycle costs (LCC). With Sleipner E Series dollies, transporting the excavator no longer stresses the undercarriage. Depending on the operating conditions and the size of the excavator, this can double or even triple the undercarriage’s service life. This translates to LCC savings of 10 to 18%.

FEWER ON-SITE REPAIRS

Excavators require regular service and maintenance, and the best place to work on excavators – in terms of access to the right tools and spares, as well as a safer working environment – is a designated workshop rather than in the field. The safe and easy relocation of excavators makes it economical to transport them to a workshop for maintenance, which is at least 20% faster than on-site repairs. This reduces excavator downtime and maintenance hours.

GET MORE DONE

Wheels under excavators bring flexibility to your operations. Heavy machinery can be effortlessly moved and relocated whenever needed, even in the middle of a shift. For example, you can take advantage of blasting breaks and fly-in fly-out (FIFO) roster changes by performing maintenance work in the workshop. If an excavator breaks down at the bottom of a pit while loading ore, just borrow a replacement excavator from an overburden area. Your valuable ore digging can then continue as planned with minimal truck waiting times.

SAFER WORKING DAYS

All Sleipner E Series operations are done mechanically with no need for human interaction. Trained truck and excavator operators can stay inside their cabs in constant radio contact. The transport can be interrupted at any time by lowering the excavator tracks, which are only around 40 cm (1.3 feet) off the ground. The maximum transportation speed is up to 15 km/h (9 mph). An automatic parking brake mechanism keeps Sleipner E Series dollies in place when not in use. These safety features minimise work-related accidents.

PERSONNEL HEALTH BENEFITS

Tramming is stressful not only for machinery but also for personnel. The vibrations can cause back problems, and shaky tramming on undulating terrain exposes the driver to other injuries as well. Furthermore, extended periods spent in the cab just to move the machine can be frustrating. When using Sleipner wheeled transportation, personnel usually experience an improvement in their quality of life, as well as fewer sick days.

Filter with weight

Notice: In order to ensure optimum equipment compatibility and performance capabilities, every truck and excavator combination must be checked on a case-by-case basis.

Site conditions are also required for the preliminary analysis.